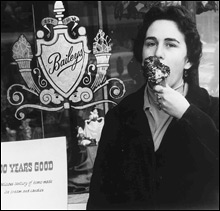

In the seventeen months between October 1978 and May of 1980, I toiled in the confectionery kitchen between Winter Street and Temple Place (opposite Park Street Station) of Baileys of Boston, Ice Cream and Confections. The main store of the seven Boston area retail stores - which included a greeting cards department in addition to an old fashioned ice cream shop and candy counter - was upstairs, the main office above that.

The singular character who taught me the art was John Lewis. John was a remarkable person at the very least due to his age when I met him - 64 - and the fact that he was still working on after I left, and with abundant energy. He used to say, paraphrasing Douglas MacArthur, "Old candy makers never die, they just melt away.".

The singular character who taught me the art was John Lewis. John was a remarkable person at the very least due to his age when I met him - 64 - and the fact that he was still working on after I left, and with abundant energy. He used to say, paraphrasing Douglas MacArthur, "Old candy makers never die, they just melt away.". He taught me to make fudge, which I produced for all seven stores in about 10 varieties: Butterscotch, Milk, Dark, Two-Tone, Maple Pecan, Marshmallow, Vanilla, Vanilla Walnut, Chocolate Walnut, Rocky Road, and Peanut Butter. I will have to check my memory on this as I may be mistaken. Fudge was a big seller and this kept me busy. But he also taught me to make candy canes, horehound drops, lemon drops, molasses kisses, peppermint, eucalyptus and spearmint drops, and I dimly recall root beer barrels and perhaps a cherry hard candy. The process was to boil up mostly cane sugar and water, with enough invert sugar (C12H22O11) to forestall recrystallization, to about 300 degrees Fahrenheit. We usually cooked up about 25 pound batches. When judged ready by the master, I took hold of one handle of the huge copper pot on the forced air stove, he took the other, and with meaningful eye contact he guided the process of pouring the molten sugar onto the table. Hot candy burns are quite serious, nearly always 3rd degree, so this was akin to the risk of neck breaking when the ballerina is hoisted high in Swan Lake.

The table was remarkable in that it was solid steel, almost 1/2 inch thick, and was equipped below with an intricate system of water pipes, through which very hot steam and very cold water could be piped in order to control the plasticity of the batch of candy. Large iron bars of one and a half inch square and of various useful lengths were placed on the table aforehand to contain the pour.The pour was made with us both tilting the kettle from opposite side of the table. One of us would scrape out the candy that had cooled and wanted to remain using a wonderfully flexible stainless spatula with a rosewood handle. I then immediately took the pot by both handles after the pour to set it on a barrel without a top used only for support at times like this. Master Lewis then added freehand the color pastes and flavor extracts needed to create the product we we needed to restore to proper stock levels. Eucalyptus was a killer since it filled the entire kitchen with an intense, palpable, scent that came close to knocking me out. Lemon and peppermint were not far behind.

My favorite was horehound, which was flavored in the pot with a tea Master Lewis brewed from whole horehound stem and leaf. But almost all followed the same routine after pouring:he would fold the candy with a spatula or sometimes his bare hand grasping the cooler edges (and I think he was showing off there), toss on the extracts and colors, which was quite a psychedelic experience since not only did it involve scent but melting bubbling blurry colors as it was worked to a uniform state, and finally become a saggy sort of mass that he would carry like a baby to the canvas covered table. This other table featured a heated bar of metal that radiated heat towards the mass of candy to keep it workable. The Master moved the candy with cotton gloved hands closer or further from the heat as needed while he worked like a chiropractor to pull the mass into a more slender cylinder of roughly 2 inches diameter.

This constantly formed cylinder of hot candy was then fed into the hand cranked machine - which I had the honor of cranking - to produce uniform drops or barrels of hard candy. The machine rollers were interchangeable to create various shapes and I had to rotate the crank at EXACTLY the right speed per the Master's directions. The candy came out the other side in stable form, thanks to the brass and atmosphere absorbing the heat, and it collected into a large pile we tossed with extra fine sugar and which we then attacked with a special scoop that would place the candy into cellophane bags on a very ancient and accurate scale. The bags were stood upright as filled and when finished I was tasked with stapling them shut with paper labels specific to each candy.

This constantly formed cylinder of hot candy was then fed into the hand cranked machine - which I had the honor of cranking - to produce uniform drops or barrels of hard candy. The machine rollers were interchangeable to create various shapes and I had to rotate the crank at EXACTLY the right speed per the Master's directions. The candy came out the other side in stable form, thanks to the brass and atmosphere absorbing the heat, and it collected into a large pile we tossed with extra fine sugar and which we then attacked with a special scoop that would place the candy into cellophane bags on a very ancient and accurate scale. The bags were stood upright as filled and when finished I was tasked with stapling them shut with paper labels specific to each candy. Candy canes, including the very large ones to be held by Santa for window displays, followed a similar process, except that half the mass of candy went right from the iron table to the hook hung on the back of a door. It was a large hook, such as for catching Jaws but not as sharp. The master always did this part himself and I will never forget the sight of him heaving the large mass of semi molten hard candy onto the hook and catching it as it oozed down each side in order to flip it over the hook again, putting gravity to work very neatly. As he continued, the candy became whiter and whiter as it filled with air bubbles. Meanwhile I was to splash pure oil of peppermint onto the candy as he directed. Thus the flavor was folded in and the white part of the candy cane made. He then joined the two and twisted them into many canes in a short time.

The chocolate making we participated in is another amazing aspect of the work. We used an interesting machine that made fondant after we poured in the correctly cooked mixture of sugar and invert sugar. It was something like a cement mixer but instead of a barrel is was an open pan about six feet in diameter with the revolving machinery that scraped the pan in the center. It was massive. Fondant formed the basis of many - but not all! - of the chocolate covered candies - milk, dark, and white - that we produced. In order to make these, for example peppermint cream centers, the Master would melt a certain amount of fondant and flavor it. He would then keep it warm while he filled up his large funnel with the mixture. He stopped the candy from escaping by using a stick about the size of a drumstick. But not stopped enough to prevent some drips of fondant to fall upon his shoes - which made him appear as one who feeds pigeons too intimately. He walked into the starch room and allowed just the right amount for individual candies to escape from the funnel and fill the molds that had been previously prepared. Each mold held perhaps 75 candies. He bent over in concentration and raised the stick up repeatedly as he moved the tip of the funnel into position and released the candy into the mold, making a thwup, thwup, thwup sound.

The molds were created as follows: about a hundred pine trays designed to accommodate fingers as they were stacked and to allow about two inches of corn starch were stored in the starch room. I was to fluff up the starch, scoop it into the trays, level the trays with a yardstick, and stack them. The master then would choose from the hanging molds and press the molds into the starch to create the shape of the candy. He would stack up as many as he needed, fill them, and re-stack them to cool. It would then fall to me to dump them into a frame with screen at the bottom, shake them a bit, and place them on trays. These would be brought in to the ladies for hand dipping in the cool room or else given to the person who placed them on the enrobing machine for machine dipping. Things like chocolate covered cherries, peanuts, and raisins had

to be hand dipped. John Lewis said more than once that whoever could invent a way to machine dip raisin and peanut clusters would be a millionaire.

The enrobing machine depended upon a source of tempered chocolate, and it was my responsibility to see to the machines for tempering being filled up. We had three that heated and conched the chocolate to keep it ready for dipping - very close to body temperature. The ladies who did the hand dipping and whose work was truly an art form of handling chocolate and designing identifying marks upon the tops with liquid chocolate also drew from the tempered chocolate reservoirs as they needed. They used a bare hand (probably softer than the Queen Mother's) that seemed to have a mind of its own they carried on conversation throughout the day and used the other hand to perform other tasks.

There was so much more - making nougats, caramels, various chocolate barks, the boxing of the chocolates, the caramel covered popcorn, the rush of holiday orders, the elementary school tours that came through, the rather solitary man, Peter, who made marshmallow and hot fudge topping almost all day long in his little room to supply the ice cream counters.... There are still some places, like Putnam Pantry in Danvers and Harbor Candy in Ogunquit , that hove to the traditional manner of confectionery. But it is a dying art, as most candy is being made by large soulless factories in multi ton batches. As a pastry chef, I still use what I learned at Baileys when I make seasonal candies or chocolates for for loved ones, wedding cakes, and other desserts. Spun sugar, caramel sauce, and my skills as a chocolatier will always find an application - until I melt away I suppose.

Spanish chef Ramon Morato was at Harvard's Cooking and Science public lecture series this past week demonstrating a few properties of chocolate for a large audience. He has written a book called Chocolate you can browse through on the web and it seems rather complete as to the history, cultivation, and technology of chocolate. You can see photos of enrobing machinery with explanation of techniques - all more or less identical to those I engaged in at Bailey's.

Spanish chef Ramon Morato was at Harvard's Cooking and Science public lecture series this past week demonstrating a few properties of chocolate for a large audience. He has written a book called Chocolate you can browse through on the web and it seems rather complete as to the history, cultivation, and technology of chocolate. You can see photos of enrobing machinery with explanation of techniques - all more or less identical to those I engaged in at Bailey's.

For an interesting history of sugar, let me recommend Sweetness and Power, by Sidney Mintz. But for living history, I am afraid I know of no place like Baileys. There was a store in Harvard Square which is one of many lost treasures of The Square. Candy and ice cream, like tobacco, became just too laden with catastrophic medical outcomes in people's minds, and ceased to be enough to sustain a store under one roof. Though of course we all know how to get our hands on both candy and ice cream now.

Rachel